Our 3D technology

How we do it

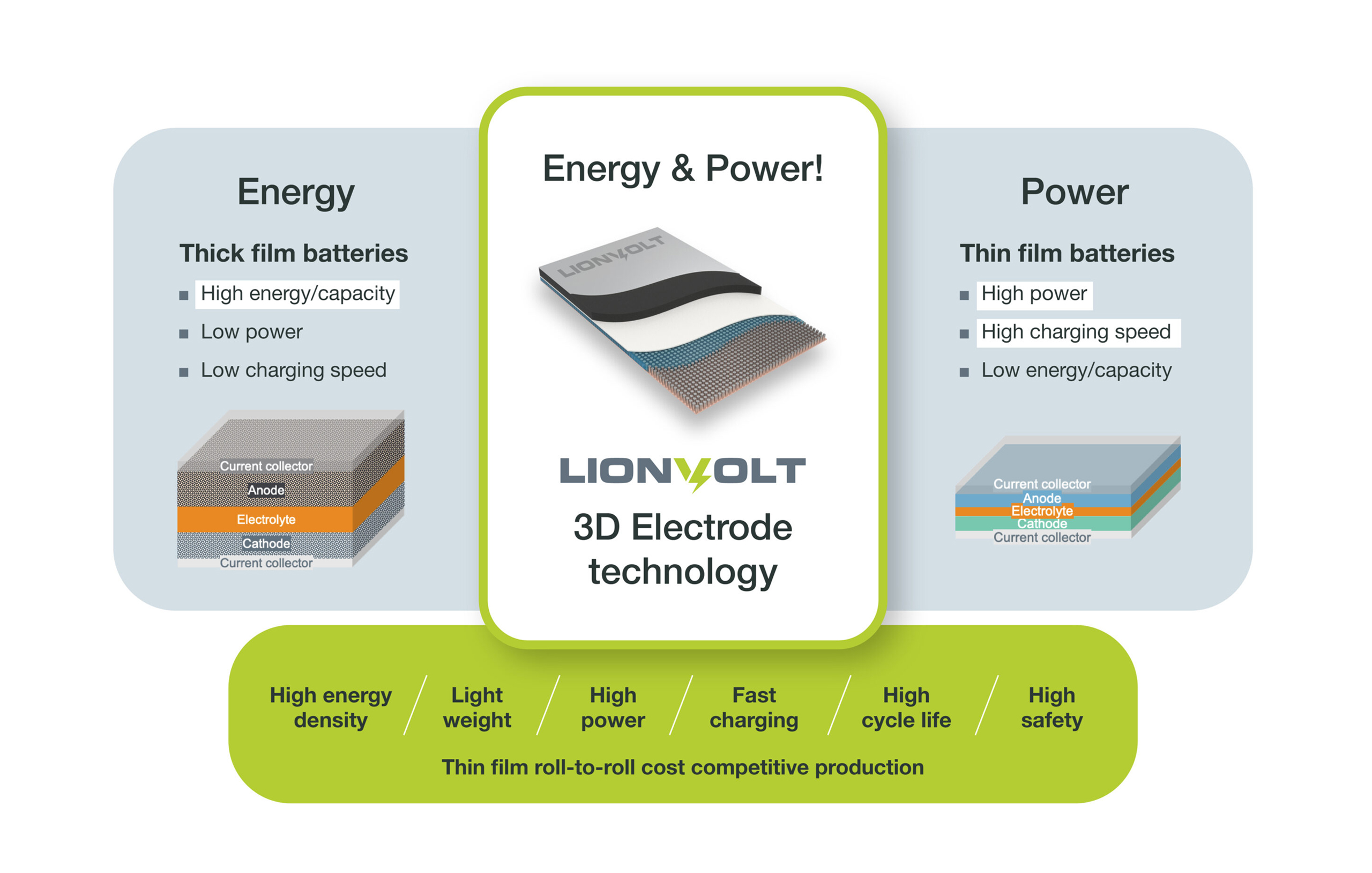

LionVolt’s combines thin-film technology and 3D structures to revolutionise the battery industry. The Eindhoven region in the Netherlands is famed for its thin film deposition know-how and manufacturing capabilities, with well-known companies such as ASML, NXP and Philips having originated in this area. Thin layer deposition is used for manufacturing of advanced chips, photovoltaics, OLED, and several other applications.

LionVolt has spun out of TNO – one of the leading European research organisations – to apply thin-films into to the world of batteries. By combining thin-film technology with 3D structured anode technology, LionVolt is able to address many of the challenges which the battery industry is currently facing. Our 3D technology is set to revolutionize the battery world as it is capable of delivering very high energy density and high charge rates. The unique 3D anode architecture can be employed across lithium-ion chemistries and beyond that in sodium-ion and solid-state. Our first product is a 3D lithium-metal anode.

This product significantly enhances the cell-level energy density when inserted into a conventional battery cell and offers fast charging at comparable cycle life/duration. It’s a drop-in solution meaning it can utilize the extensive build out of Gigafactories being constructed today. Beyond this, our technology will enable long-duration solid state cells with a step change in energy density and with superior safety as the liquid/flammable element of the cell is removed.

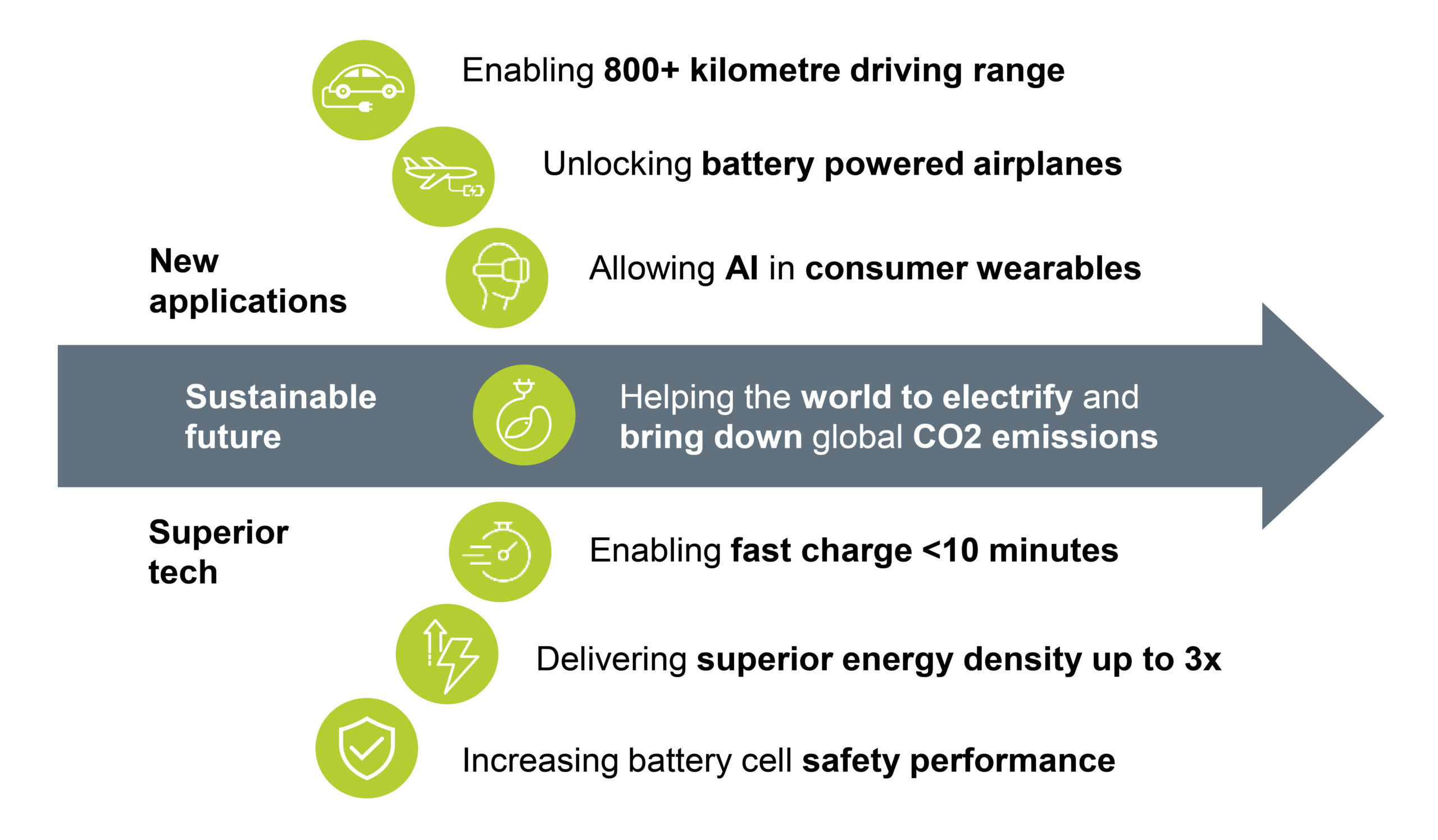

Superior battery technology for consumer electronics, aviation and electric vehicles

Markets and Appliances:

Consumer Electronics & Wearables

The demand for battery performance in the consumer electronics and wearables applications continues to grow. There is a strong demand for higher energy density battery cells that support a longer battery life and help to decrease device weight and size. This is particularly important as devices increasingly rely on more energy-demanding functionalities. LionVolt’s 3D anode technology enables substantially smaller and lower weight battery cells without compromising the battery capacity or battery life. Our 3D anodes increase cell-level energy density by 1.5-2x and can be seamlessly dropped-into the existing cell supplier manufacturing process.

Drones & Aviation

It’s only a matter of time before electric battery-powered aircrafts take to the skies. Energy density of battery cells is a key enabler of drones and electric aviation. The energy density of a cell directly translates to flight time and the ability to increase aircraft/drone weight. LionVolt’s 3D lithium-metal anodes help to increase cell-level energy density by 1.5-2x. At the same time, the ground-breaking 3D architecture supports high charge and discharge rates, meeting the requirements of the drone and aircraft market. In addition, our 3D lithium-metal anodes can be integrated in solid state cells with a step change in energy density and with superior safety as the liquid/flammable element of the cell is removed.

Electric Vehicles

Despite the rapid growth of electric vehicle (EV) adoption in many developed regions, widespread mass-market uptake remains hindered by several factors. Extended driving range continues to be a barrier for potential consumers, alongside the limited availability of affordable, compact EVs that offer sufficient driving range. LionVolt’s 3D structured anode is a key enabler for next generation batteries that will help to further drive the electrification transition in this market. LionVolt’s first product for the BEV market is a 3D lithium-metal anode. This product delivers 1.5-2 times higher cell-level energy density when inserted into a conventional battery cell and is compatible with NMC and LPF cells. It supports a <10-minute fast–charge and offers comparable cycle life/duration compared to conventional cells. The 3D anode production process is based on a low cost and highly scalable roll-to-roll manufacturing approach. This results in high performance cells which are at cost parity compared to today’s cells.